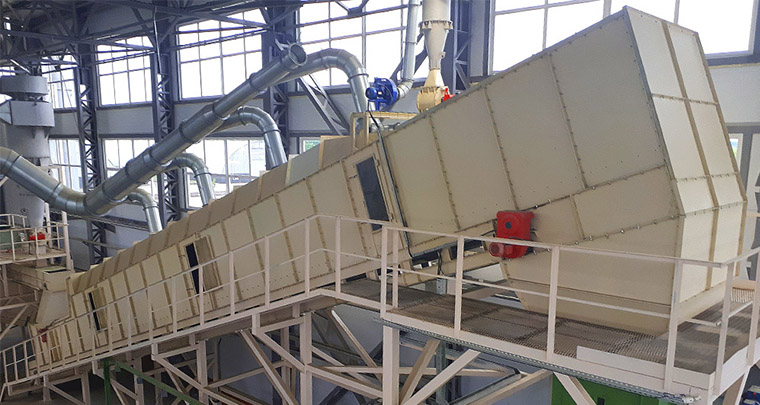

When developing different production lines, their optimal operation requires equipment that is not serially produced. The best solution in such cases is to manufacture customised equipment.

We offer designing, manufacturing and commissioning of equipment of the required size and functionality with warranty and post-warranty service.

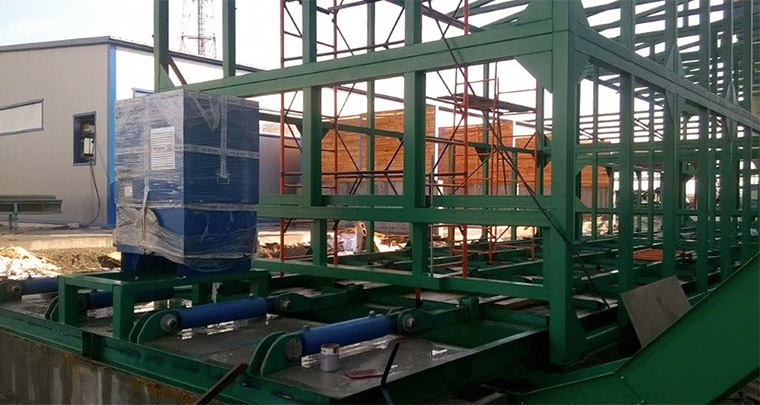

Special metal structures such as service platforms, supporting and enclosing constructions are indispensable parts of technological lines and equipment. Our company manufactures metal structures individually for each project.

LesInTech's design department and sufficient production capacity allow us to produce and deliver just-in-time everything you need according to your order.

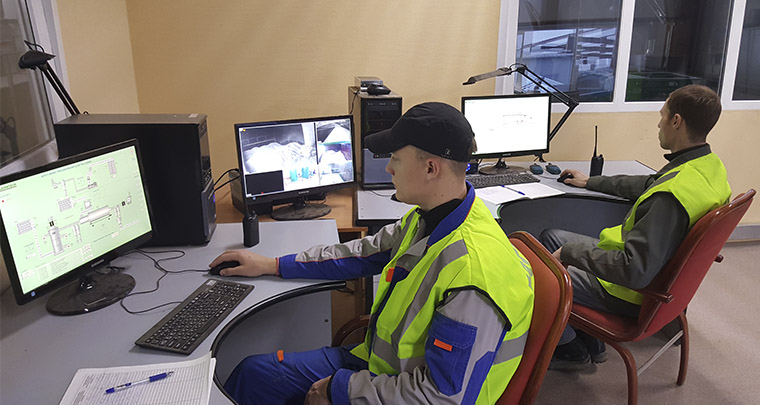

LesInTech offers the development, design, manufacture and installation of low-voltage switchgears for the distribution of electrical energy and process automation of various systems according to individual requirements and typical schemes.

We take care of all issues in the field of automation and control of equipment produced by our company.

Begin your cooperation with our company before starting the production. We provide consulting services for the design and development of equipment specifications, which is an integral part of the preparation of the production process.

This professional engineering service enables us to determine the optimum composition of production lines, parameters, raw material balances and energy consumption. The resulting data makes it possible to estimate the cost and profitability of a project.

Knowing the efficiency of your process equipment enables you to optimize your production processes in order to reduce production costs and increase the output of your products;

identify production bottlenecks and determine the reliability of components and mechanisms in current production facilities.

Technical refurbishment of production facilities is aimed at increasing productivity and stability of operations and can be carried out both on an integrated and pointwise basis.

We duplicate technological lines, add production areas to expand the range of raw materials consumed, as well as replace inefficient equipment or install additional equipment, eliminating bottlenecks.

We are able to provide a full range of services related to production start-up. This enables you to get your production up and running without any intermediaries.

We will train your employees in the use of the new equipment and provide full operational advice. Both management and operation staff will be prepared for all production situations, ensuring that the lines are used competently and efficiently.