- Operating principle

- Features

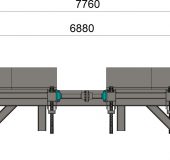

- Specifications

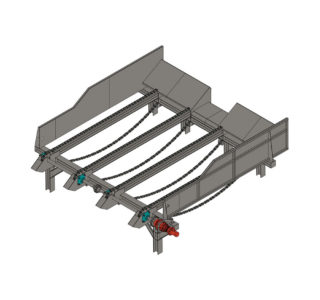

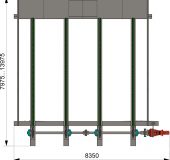

A loading table is special equipment designed to provide a short-term supply of logs and to feed them to the log rolling table or batch disconnector. The log chain conveyor is mostly used to reduce the stack layer before feeding the material to the batch disconnector.

The basic principle of operation of this type of mechanism is as follows:

- First, the logs are loaded in organised piles to form a stack in a position perpendicular to the chain movement direction;

- Then, by rotating the drive shaft, the entire load is conveyed along the entire table;

- Lastly, the gear motor drives the chain, after which the logs can be unloaded over the table edge.

To purchase a log chain conveyor directly from the manufacturer at the best price, simply fill out the form on the website. Our specialists will answer all your questions and process your order.

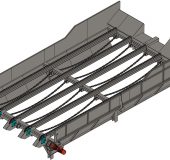

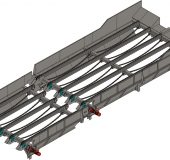

- The tables for this type of machinery are manufactured in two versions (both with four and five guides) according to the customer’s specifications.

- The machinery is equipped with load chain guides made of PE-1000 high-molecular plastic.

- The device is equipped with a mechanical drive with an orbital gear motor, as well as special sides that prevent the logs from rolling away randomly.

Log length 2 to 6.5 m

Volume max. 40 m³

Gear motor Brevini

Bearings NSK/ Asahi/ SKF

Chains European or Russian made

Material structural steel

Paint finish RAL 5024 (Tikkurila). Customisable colour.