In order to receive, store and unload pellets, wood chips or household waste, it is necessary to buy a bulk material hopper. There are two types of process tanks that are most common in Russia: receiving (storage) hoppers and feeding (unloading) hoppers.

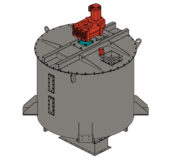

- The mechanised device for collecting, storing and buffering solid bulk materials is a cylindrical tank. The materials are moved inside by an agitator. Loading is carried out from any conveyor. Service hatches are provided for inspection, and the position of the windows depends on the specifics of the process line.

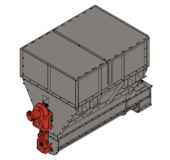

- Feeders with a capacity of 2.4 to 20 m³ are designed for dosing bulk materials. The dosing screw automatically feeds the next batch to the conveyor or to the vehicle. The feeding system can be installed indoors or outdoors. It operates at temperatures from -20°C to +40°C.

LesInTech offers the manufacture and sale of customised technological hoppers based on the customer’s production needs. The body and screws are made of structural steel. Galvanised fasteners are used to prevent premature corrosion.

The overall cost of a hopper is mainly determined by its volume. In addition to manufacturing the required hopper equipment with a quality guarantee, we also deliver, install and commission it. This is a good value for money!