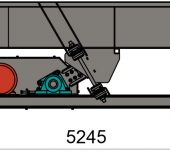

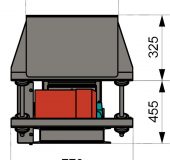

The dimensions and specifications of the equipment are agreed upon individually and depend on the functions required.

- Operating principle

- Features

- Specifications

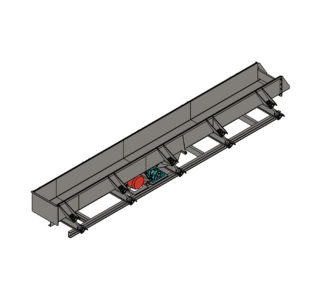

Основной принцип работы вибрационного конвейера заключается в подаче целенаправленных вибраций. Они толкают крупнокусковые отходы лесопильной отрасли в сторону рабочих (рубящих) элементов.

Иными словами внутри устройства происходят не просто колебания, а направленные колебательные движения. Именно поэтому рабочий процесс вибротранспортера полностью предсказуем и управляем. Координировать необходимое перемещение грузов не сложно, и даже можно влиять на характеристики работы прямо в ходе ее. Возбудители вибрации можно основывать и выше, и ниже желоба, не влияя на практические показатели оборудования.

Our vibrating conveyors are perfectly suitable for use in sawmills and wood processing plants. Most drives have an output of at least 3,000 watts, which enables a sufficiently large payload flow through the load-carrying channels.

The specific parameters of the load-carrying vibrating conveyor are specified in the technical data sheet. It is possible to produce a device with a mesh bottom and a separation mode for foreign particles from the conveyed wood.

Capacity max. 10 m3/h

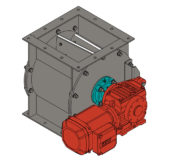

Drive power 3 kW

Bearings NSK/ Asahi/ SKF

Materials structural steel

Motor SEW-EURODRIVE or Russian-made ones

Conveyed material coarse wood waste

Paint finish RAL 1015 (Tikkurila). Customisable colour