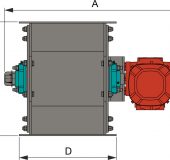

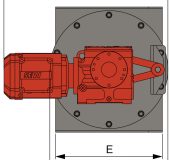

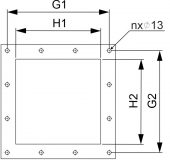

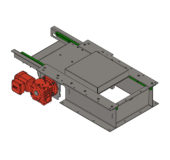

The rotary valve is available in the following standard sizes:

|

Standard size |

A |

B |

C |

DxE |

F |

G1xG2 |

H1xH2 |

n |

|---|---|---|---|---|---|---|---|---|

|

RV-300 |

665 |

585 |

410 |

350×350 |

386 |

312х312 |

260×260 |

12 |

|

RV-400 |

757 |

640 |

526 |

366×366 |

487 |

330х330 |

270×270 |

12 |

|

RV-500 |

920 |

697 |

696 |

466×466 |

601 |

420х420 |

370×370 |

12 |

|

RV-600 |

1000 |

780 |

750 |

566×566 |

691 |

522х522 |

470×470 |

12 |

|

RV-800 |

1347 |

964 |

1000 |

988×766 |

912 |

950х728 |

892×670 |

16 |

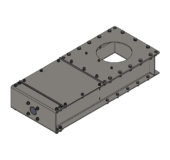

Specifications depending on the model:

|

Model |

Power, kW |

RPM |

Operating voltage, V |

Current, A |

Capacity, m³/hour |

|---|---|---|---|---|---|

|

RV-300 |

0.75 |

21 |

230/400 |

3.15/1.8 |

18 |

|

RV-400 |

1.1 |

21 |

230/400 |

4.15/2.4 |

43 |

|

RV-500 |

1.1 |

23 |

230/400 |

4.15/2.4 |

98 |

|

RV-600 |

1.5 |

24 |

230/400 |

5.7/3.3 |

170 |

|

RV-800 |

3 |

24 |

230/400 |

335 |