- Operating principle

- Features

- Specifications

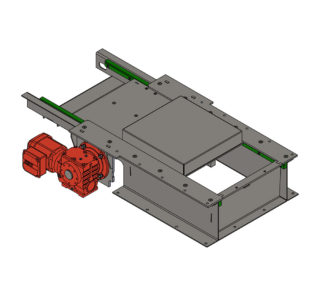

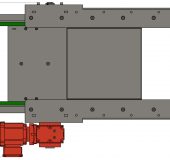

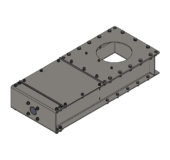

Электромеханический затвор для сыпучих материалов предназначен для отвода продукта, перемещаемого цепными конвейерами с нижней приводной линией. Работа этих конвейерных систем заключается в перемещении скребков, прикрепленных к тяговым цепям и опускаемых в продукт.

Сам продукт располагается в неподвижном лотке. Электромагнитный клапан останавливает и возобновляет поток материала, поворачиваясь на определенный угол внутри корпуса клапана. В этих типах клапанов используется электропривод червячного типа.

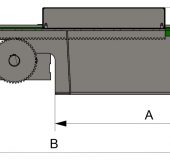

Цилиндр жестко прикреплен к корпусу клапана через балку и кронштейн. Модели различаются по размерам и характеристикам.

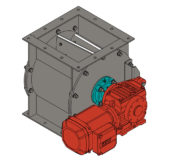

Solenoid valves are used in hoppers, dosing units and other systems for handling bulk materials (cement, sand, grain, etc.).

The equipment has some technological peculiarities:

- Three inductive sensors are included in the standard specification to allow valve position adjustment (open, closed, intermediate position);

- Design includes mechanical protection against sensor failure;

- Valve slides on special guides made of durable plastic;

- False bottom prevents material from jamming and damaging the scraper;

- Valve has a switch to control closure and readiness for material loading.

Our company specialises in selling solenoid valves and offers delivery, installation and commissioning services.

Gear motor SEW-EURODRIVE

Bearings NSK/ Asahi/ SKF

Fixing material galvanised

Body structural steel, stainless steel

Guides PE1000 high-density polyethylene

Paint finish RAL 1015 from Tikkurila. Customisable colour