- Operating principle

- Features

- Specifications

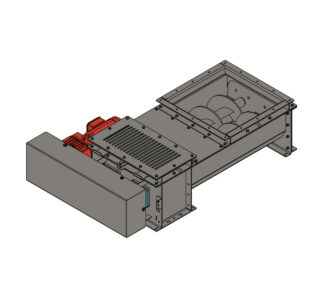

Двойной шнековый конвейер работает посредством:

- Горизонтальный паз;

- Полуцилиндрическое дно;

- Два винта определенной длины.

Шнековый конвейер по сути будет представлять собой камеру с внутренними спиралями, внутри которой перемещаются сыпучие материалы. В этой конструкции две винтовые части используются для расширения окна выгрузки. Сыпучий материал поступает внутрь конвейера через желобчатые отверстия. Он выгружается через днище, оборудованное клапанами.

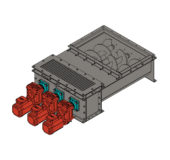

The screw conveyor ensures the conveying of large quantities of the required raw material. As the unit is easy to disassemble, repairing and replacing the main components poses no problem. Transporting the equipment is also simplified.

Screw conveyor overload and emergency stop is indicated by:

- Service hatch,

- Rotation sensors.

Additional parts can be insulating hoods for gear motors and remote bearing lubrication systems.

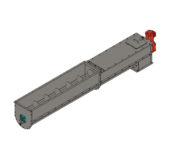

Number of screws 2

Screw length max. 6 m

Screw diameter 100-800 mm

Gear motor SEW-EURODRIVE

Bearings NSK/ Asahi/ SKF

Construction material structural painted steel, galvanised, stainless steel

Paint finish RAL 1015 from Tikkurila. Customisable colour