- Operating principle

- Features

- Specifications

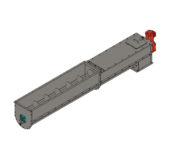

Шнековый конвейер доступен в широком ассортименте конструкций и внешних размеров в зависимости от требуемого применения. Сыпучие материалы транспортируются:

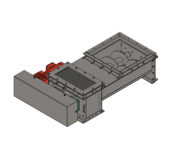

- Горизонтальный паз;

- Низ (полуцилиндр);

- Винты указанной длины.

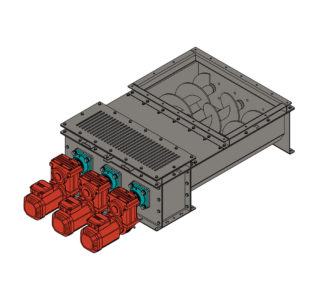

Оборудование доступно в трех- или четырехшнековой конструкции. Количество шнеков определяет не только размер, но и общую производительность машины. Поток материала в обслуживаемый объем определяется отверстиями желоба. Материал выбрасывается из винтовых конвейеров через дно (с помощью клапана).

Устройство может перемещать большие объемы продукта и точно дозировать их.

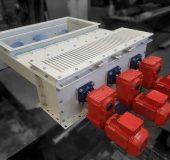

To simplify possible repairs and maintenance, the screw conveyors are implemented in a modular design. Rotation sensors and signalling devices, irrespective of the diameter and number of screws, are installed to ensure that the conveyor is not overloaded. A service hatch is also provided to monitor the screw overload.

Our screw conveyors are always the optimum choice for handling a wide variety of goods and materials. However, more often than not, designs are adjusted to the requirements of the particular industry. That is why additional options can be fitted:

- Remote bearing lubrication units;

- Hoods for mechanical insulation of the gear motor.

Number of screws 3-4

Screw length max. 6 m

Screw diameter 100-800 mm

Gear motor SEW-EURODRIVE

Bearings NSK/ Asahi/ SKF

Construction material structural painted steel, galvanised, stainless steel

Paint finish RAL 1015 from Tikkurila. Customisable colour