- Operating principle

- Features

- Specifications

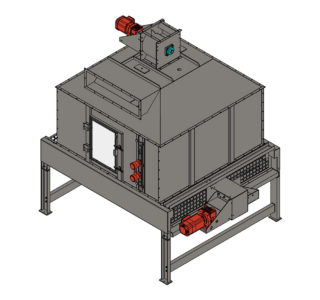

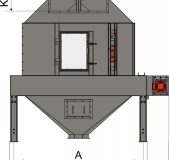

Противопоточный охладитель — это аппарат, предназначенный для охлаждения частиц комбикорма и пеллет. Чаще всего данное оснащение используется при охлаждении кормовых и древесных гранул, а также гранул целлюлозы и других подобных продуктов.

Принцип работы оборудования состоит в том, что сырье непрерывно подается в основную камеру через впускной клапан, где и формируется равномерный слой с заданной высотой. За счет разрежения через слой гранул проходит холодный поток воздуха, который отбирает избыточное тепло от продукта.

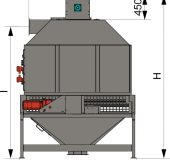

По мере охлаждения, нижний слой продукта переносится в разгрузочную камеру при помощи подвижной решетки с электроприводом, что обеспечивает плавную разгрузку.

- The cooling chamber is made of mainly structural and stainless steel.

- The pellet temperature at the inlet is max. +90°C and at the outlet +10°C of the cooling air temperature.

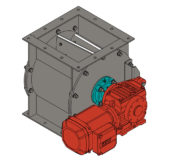

Gear motor SEW-EURODRIVE

Materials structural, stainless steel

Paint finish RAL 1015 Tikkurila (customisable colour)