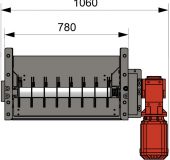

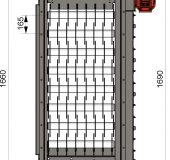

The equipment dimensions are agreed upon individually depending on the functions to be performed.

- Operating principle

- Features

- Specifications

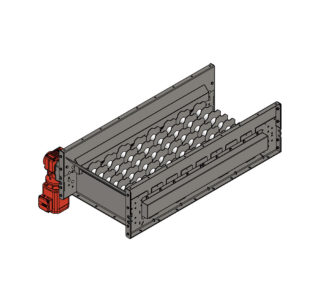

Дисковый сепаратор предназначен для сортировки сыпучих материалов (в том числе древесины и древесных отходов: опилок, щепы, коры). Устройство состоит из рамы, роликов с дисками и мотор-редуктора, обеспечивающего крутящий момент. Соседние ролики приводятся во вращение цепной передачей.

В дисковом сепараторе диски съемные, что позволяет изменять расстояние между дисками. Исходный материал требуемых размеров (кондиционный материал) проходит через зазоры между вращающимися дисками и выгружается снизу. Вращающиеся диски перемещают некондиционный материал по поверхности к месту выгрузки.

The customised disc separator offers the following technical advantages in all sizes:

- The gear motor can be located on either side of the equipment.

- Quick-release hatches allow visual inspection of the main components.

- Plastic guides made of PE-1000 to reduce chain wear.

Output particle size and capacity depend on the distance between the separator discs. Increased capacity is achieved by raising the number of rollers, the separator width and the drive speed.

Gear motor SEW-EURODRIVE

Bearings NSK/ Asahi/ SKF

Operating temperature -20 to +40°C

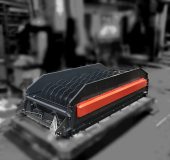

Type of material to be screened wood chips, sawdust, bark

Materials structural steel, galvanised steel, stainless steel

Paint finish RAL 1015 (Tikkurila). Customisable colour