The size and capacity of the vibrating screen is individually selected depending on the material to be screened.

- Operating principle

- Features

- Specifications

Виброгрохот — это специальное оборудование, предназначенное для разделения сыпучих материалов на одну или несколько фракций. Работа этого устройства осуществляется его просеивающими поверхностями с калиброванными отверстиями. Маховики вращаются асинхронным двигателем через ременную передачу.

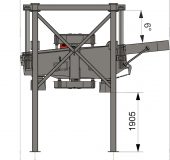

Просеиваемый материал засыпается на верхнее сито через специальное загрузочное отверстие. Затем частицы сырья начинают подпрыгивать и двигаться по спирали. Частицы, меньшие, чем сами отверстия, сбрасываются на нижнее сито. Более крупные частицы направляются к отверстиям на периферии. После этого частицы выгружаются через патрубок в сборный резервуар, через который они попадают в отстойник.

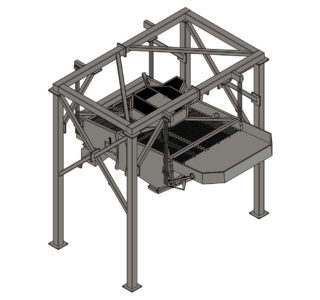

This vibrating screen is used for processing wood chips, sawdust and other timber products. The unit of any selected size has the following features that ensure a quality and comfortable working process:

- Quick-release screens for different raw material fractions.

- Service hatches for adjusting the flywheels.

Vibrating screens designed by our company are supplied with a modular frame.

Mean capacity min. 80.0 m³/h

Material to be screened chips, sawdust

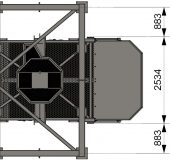

Working area of upper sieve 7,6 м²

Working area of the lower sieve 6,0 м²

Motor SEW-EURODRIVE or Russian-made one

Bearings NSK/ Asahi/ SKF

Material structural steel

Paint finish RAL 1015 (Tikkurila). Customisable colour.