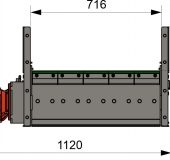

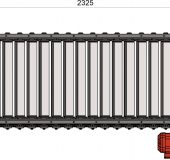

The dimensions of the equipment are agreed upon individually and depend on the functions to be performed.

- Operating principle

- Features

- Specifications

Валковый сепаратор предназначен для отделения крупных частиц сыпучего материала от мелкой фракции. С помощью этой сортировочной машины можно сортировать следующие материалы:

- Древесина,

- Древесные отходы (опилки, щепа, кора),

- Бытовые отходы.

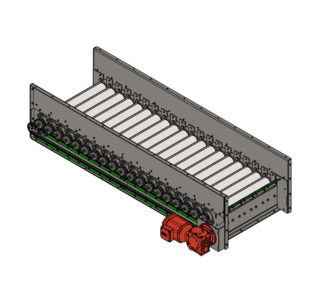

Привод агрегата осуществляется цепной передачей с использованием электромеханического привода. Размер просеиваемых частиц зависит от диаметра роликов и расстояния между ними. Повышение производительности достигается за счет увеличения количества роликов, ширины клетки и скорости привода. Ролики изготавливаются в различных исполнениях в зависимости от требуемого применения.

The roller separator is made of high-strength structural steel and all plastic guides are made of PE-1000 ultra-high molecular polyethylene, which significantly reduces wear and tear on the chain. Regardless of the dimensions selected, the equipment has the following technical advantages:

- Quick-release hatches for visual inspection of the main components.

- The sprockets on the chain drive system allow for easy replacement.

- Quick-disassembly frame.

Gear motor SEW-EURODRIVE

Bearings NSK/ Asahi/ SKF

Type of material to be screened wood

Material Structural steel

Chain made in Europe or Russia

Paint finish RAL 1015 (Tikkurila). Customisable colour.