- Operating principle

- Features

- Specifications

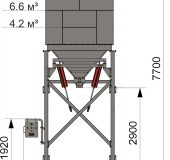

Машина для упаковки в биг-бэги (далее – МФБ) – это специальное оборудование для автоматической фасовки сыпучих продуктов (пеллет, гранул и т.п.) в 2-х или 4-хрядные мягкие контейнеры типа «биг-бэг».

Оборудование для упаковки в биг-бэги пользуется большой популярностью у производителей сухих строительных материалов, в сельскохозяйственном секторе, а также в других компаниях, использующих различные виды сыпучего сырья.

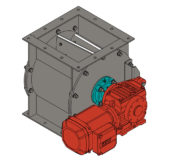

БМП, производимая нашей компанией, представляет собой предварительно сварную металлоконструкцию, состоящую из следующих частей:

- Опорная рама.

- Приемный бункер.

- Весовой механизм.

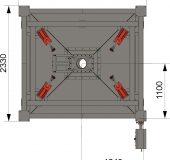

- Дозирующий и наполнительный блок.

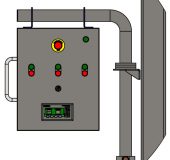

- Шкаф управления.

- Пневматическая система с приводами, трубопроводами, органами управления и запорными элементами.

The main characteristics of this equipment are as follows:

- The station’s control system allows operating it both as an independent unit and as part of the enterprise’s automated control system (ACS).

- The unit can be optionally equipped with a dust aspiration system and a diverting rollway bearing (gravitation or driven).

- The capacity is 15 containers per hour.

- The temperature of the products to be filled may not exceed 80°C.

- The dosing tolerance of the BPM with material up to 1,000 kg is +/- 1 count, where 1 count equals 1 kg.

Installation conditions +5 to + 40°C

Power consumption 0.5 kW

Hopper capacity 4.2 m³ to 13.8 m³

Mass 2,300 kg

Capacity 15 containers/hour

Temperature of the products to be filled max. 80°C

Soft container width max. 1,100 mm

Soft case height 1000-2000 mm

Filling spout diameter 200 mm

Max. weighing limit 2000 kg