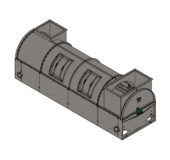

Однопроходный сушильный барабан для щепы, трав и других влажных веществ функционирует как часть сушильной системы. Помимо основной сушильной части, для производственной линии требуются теплогенератор, пневматические устройства и загрузочно-разгрузочные механизмы.

В однопроходной конфигурации полная сушка происходит внутри одного резервуара. Поэтому для сушки в барабане рекомендуется сырье, не требующее изменения режимов работы по мере снижения влажности. Вращение цилиндрического барабана перемешивает содержимое.

Лопасти на стенках поднимают материалы вверх при вращении, после чего они свободно падают через поток теплого воздуха. В результате влага испаряется. Так сушат растительное сырье, картонную тару, пеллеты и гранулы.

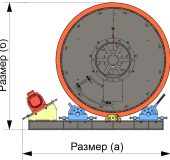

- Continuous roller lubrication with graphite.

- Installation of cast tires on spacers.

- Availability of durable support frames.

- Heat insulation on the entire surface.

- 4-roller design.

The load-bearing drum elements are made of structural steel. A toothed ring is used for activation, thus eliminating slippage.

The country of manufacture is Russia. A gear motor and bearings are fitted to the drum. The permissible ambient temperature range is from -35 °C to +40 °С.

Coating colour can be changed on request. With a stainless steel cylinder lining, the industrial drum dryer for bulk materials is highly resistant to corrosion.

Gear motor SEW-EURODRIVE

Bearings NSK/ Asahi/ SKF

Operating temperature -35 to +40 °С

Body structural steel

Banding structural steel

Frames structural steel

Paint finish RAL 1015 from Tikkurila. Customisable colour