- Operating principle

- Features

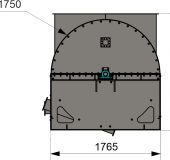

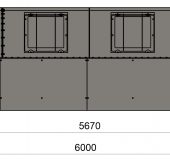

- Specifications

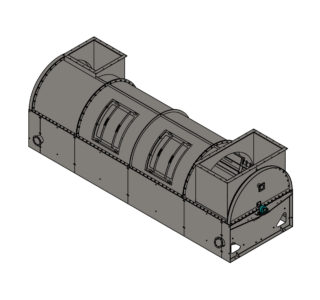

Роторный сушильный барабан в первую очередь предназначена для сушки сырья, полуфабрикатов и готовой продукции. Также ее можно использовать для сушки вторсырья и твердых бытовых отходов, в частности, влажной картонной тары.

Современные барабанные сушилки для сыпучих грузов универсальны в своей работе и подходят для обработки широкого спектра веществ. На практике чаще всего сушат опилки и гранулы. Роторная сушилка для опилок состоит из статора и ротора. Статической частью является корпус, и для установки оборудования не требуются стойки или дополнительные конструкции.

Редукторный двигатель, соединенный с цепным приводом, вращает цилиндр барабана внутри рамы. Подшипники минимизируют трение. Для погрузочно-разгрузочных работ используются винтовые конвейеры.

- The dryer is suitable for drying groceries.

- The painted parts are coated with wear-resistant enamel.

- The drum is additionally insulated over its entire surface.

The hygienically safe drum dryer for groceries is free of components posing a risk to human and animal health. The mobile hopper is made of customised structural or stainless steel. The default colour can be changed to any other colour as required by the customer.

The prefabricated rotary dryer equipment is easy to install in production and can be upgraded on site if required. For repair and maintenance, rotary drum dryers are only temporarily shut down with no need for disassembly.

Gear motor SEW-EURODRIVE

Bearings NSK/ Asahi/ SKF

Material structural steel, stainless steel

Performance max. 2 tonnes of evaporated moisture

Paint finish RAL 1015 from Tikkurila. Customisable colour.