- Operating principle

- Features

- Specifications

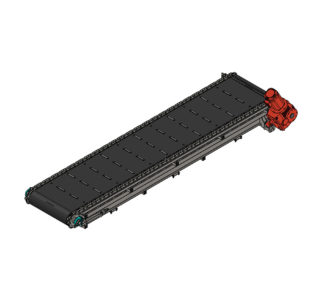

Belt chain conveyor is a particular type of equipment with a conveyor belt. It is only responsible for carrying the load. The pulling force is transmitted by chains of different lengths.

When the belt runs on the upper band, it moves on rollers mounted on top of a frame. On the bottom band, the chain-driven conveyor transports the goods by running chains on wear-resistant steel bands. The belt runs on guide rails.

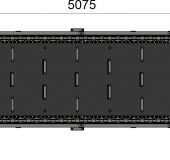

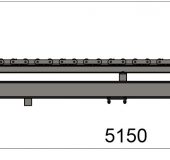

On the belt section, loads can be conveyed at an inclination of up to 30 (and even 33) degrees. The curvature radius is at least 4 m and is sometimes increased to 8 m or more. The width of the conveyor band varies from 65 to 100 centimetres. In 60 minutes, 300-500 tonnes of payload are transported.

- With rigid connection of chains to the belt surface;

- With a friction connection.

Gear motor SEW-EURODRIVE

Bearings NSK/ Asahi/ SKF

Materials of construction structural steel

Chains European or Russian made ones

Paint finish RAL 1015 from Tikkurila. Customisable colour